- today

- label Guide

- favorite 0 likes

Passive welding helmets and shields have tinted glass with a properly selected, constant degree of tinting. Passive welding helmets should be put on the head, lowered before the arc strikes and lifted up after finishing welding. The shields must be held in the hand by placing it in front of the eyes and face during welding, and moved to the side after stopping welding. When using a shield, good hand coordination is essential to avoid eye injuries.

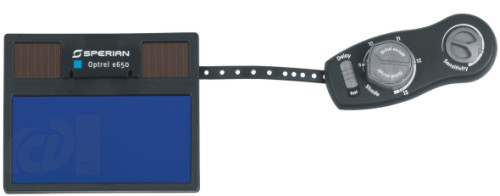

Active welding helmets are called Auto Darkening Filter and are equipped with an Auto Darkening Filter (ADF) welding filter. When welding starts, the filter automatically increases the shade level without causing glare. It also brightens when the welding arc is turned off. Without removing or tilting the helmet, the workpiece is visible almost all the time.

ADF filter - principle of operation

The basic elements of the ADF filter are the LCD liquid crystal display and arc sensors. The principle of the LCD screen is similar to a shutter. When there is no energy supply, the screen is translucent. This condition is generally referred to as the bright state - usually in shade 3 or 4. When the arc is struck, the sensors send an electrical signal that powers the LCD and the screen darkens immediately. It is a dark state which can mean a single shade level, e.g. 11, or variable shade levels e.g. from 9 to 13 depending on the setting. After the arc disappears, the LCD screen returns to a bright state.

The ADF filter is usually powered by light-sensitive cells that extract light energy from the electric arc. To maintain operation when the ADF filter is used after a long period of inactivity, it is also equipped with batteries.

ADF filter protected against dirt and mechanical damage by means of external and internal glass.