- today

- label Guide

- favorite 0 likes

Work gloves - how to choose, what to look for?

As always in my case, the subject of the river, I have to restrain myself from gibberish. However, I will try ... briefly and to the point. We do not pay much attention to the purchase of gloves, because it wears out quickly, and because it gets lost, employees do not respect it, and so on. As a result, we buy just about anything, not suited to our needs, without any properties that could help us at work. Because did you know that suitable models of gloves have already been created for specific professions? Have you heard that you can use comfortable and flexible knife-resistant gloves? (we checked, they do not intersect).

Should you finally think about gloves only in terms of "how long it will last"? After all, when buying other items of clothing, we don't just think about durability. We value comfort, functionality, whether we will walk, run or work well in it.

Ok, ok, but where to start? As always, before proceeding with the purchase, please take 5 minutes to list your routine activities with your hands / hands. Do you need very good precision, manual skills, or do you do a hard job where comprehensive hand protection against damage is required? Do you work in a dry place with clean objects, or in a dirty workshop, changing oily screws all day? Answering these questions will allow you to choose the right type of glove, material, coating and additional features that can make your work enjoyable.

One more important thing ... we worry about the purity of our air, we eat natural products, and later at work we put gloves on our hands, made of materials containing harmful substances, sensitizing, and emitting unpleasant odors. We will devote a short note to this thread when describing the materials used for production.

So to the point ...

As always, size matters - work gloves and their dimensions

This story was told to me by one of my friends who used to supply industrial plants with gloves. There has always been a problem there as the staff did not want to wear gloves. Turns out everyone was getting the same size gloves ....

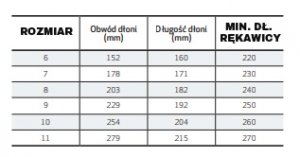

Basically, we have 6 sizes of gloves on the market, from 6 to 12, where 6 is a rather feminine size, 12 is a really huge size. Unfortunately, there is no uniform and realistically standardized size of work gloves. A lot also depends on the model you choose (flexible gloves are easier to fit, while leather gloves should be individually fitted to the size of your hand). Why does size matter? Too large gloves reduce our precision and weaken our grip. The risk of an accident is also increased - for example, when a machine gets caught in a loose part of a glove. A work glove that is too large will also wrinkle in the grip area and leave play on the fingertips. On the other hand, gloves that are too small contribute to the disturbance of proper circulation, and thus you will experience fatigue of your hands faster while working.

Also remember that the use of too small protective gloves puts a lot of stress on the seams of the gloves, which reduces their durability.

How to cope? Below we present a very imprecise but still table of sizes of work gloves, we hope it will help. If you have the opportunity to try it on, you can calmly check that the fingertips are tightly wrapped by the gloves and that there are no folds on the hand, that the glove is wearing well, is not pinching.

Unfortunately, there are problems with online shopping, in online stores, because it is impossible to try on. In this case, we recommend testing different manufacturers and shopping in stores that offer hassle-free returns :).

Please stand up, science is coming - two words about materials

What are the most common protective gloves made of? The most popular materials are, of course, nylon and polyester, from which the glove shell is made. The second most popular material is ... leather, from which many models are made for work in heavy industry, welding, but also precise assembly gloves. The third group consists of plastic gloves - nitrile, latex, butyl, and many, many others. They provide protection against water and chemicals. You can also say about hybrid gloves, made of mixtures of leather, artificial materials and materials specially developed for the needs of a given product, e.g. the Chamude fabric from Snickers Workwear. An interesting group of gloves are also anti-cut gloves - yes, the spelling is correct. These are gloves made of fibers resistant to knife cuts - for example Dynema, or cheaper models of fiberglass.

Of course, at Balticbhp.pl we also have something that others do not have, an absolute market hit, i.e. innovative gloves made of graphene fiber. Extremely light, flexible, very breathable, and in addition heat-resistant and partially cut-resistant.

What material to choose? What will be good for your job? The answer, as always, is - it depends on what you do. Rely on and demand professional service in workwear stores. Ask, check knowledge and provide feedback.

What is worth paying attention to?

When choosing gloves, pay attention to the composition of the material, choose gloves made of fibers enriched with spandex, lycre, stretch. These materials are characterized by very good flexibility, which affects the comfort and use - they do not tire the hands, they fit better.

It is also worth choosing gloves with the Oeko-tex certificate - which certifies that the product is made of materials that are safe for you and your environment. Remember, you wear gloves for hours on your skin. Make sure not to harm yourself.

Glove construction - does it really matter?

Have you ever heard of gloves that help your hands rest? If not, it is worth paying attention to this parameter. Often you wear work gloves on your hands all day long. However, you don't do work all day with them. It would be good for your hand to be in the position of the so-called rest, that is, resting. During these breaks between activities, well-sewn and technically advanced gloves will allow your hand to relax and rest. Simple isn't it?

Have you ever felt that after 5 minutes of using the gloves you felt like throwing them into the trash can because your hands literally burn? This is the result of insufficient hand ventilation and possible allergic reactions to the materials contained in the gloves. Therefore, it is worth choosing models of gloves that offer hand ventilation systems, such as actifresh in Ninja gloves. Is it as good as air conditioning? Unfortunately, no, but just put on gloves with a solid ventilation system and you will immediately feel the air flowing around your hand. It really helps in a day-long fight.

Let's also remember about hygiene. Our hands, of course, sweat as we work. In addition to adequate ventilation, it is worth providing them with a hygienic environment. We will achieve this effect by using protective gloves with stitching of antibacterial materials that prevent the growth of bacteria and unpleasant odors. We should also remember that protective gloves made of synthetic materials can be washed without compromising their protective properties.

Two left hands? It makes sense

Seemingly simple, yet not everyone thought about it. Do both of your hands do the same things all day long? One holds a nail, the other a hammer, one holds the saw, the other holds the wood, one holds the screw and the other holds the screwdriver. So why think about gloves in a template way? At this point, bows to the Snickers Workwear brand, which allows users to buy gloves left and right separately. Your hands do different jobs, so they need different parameters and different protection. We like this solution, it makes sense.

What to wear to catch well?

Something that customers usually don't pay attention to or even know what to look for. The material and structure of the coating used in the grip area of the glove is critical to its use. The most commonly used materials are: latex, nitrile, vinyl, polyurethane. How are these materials different? Let's start with latex, latex is a natural rubber whose coating is characterized by very good adhesion and flexibility. Latex-coated gloves are often used in construction, transport work. A relatively new material is latex foam - soft, it provides even better grip and grip. Latex, on the other hand, does not cope well with abrasion and work in an oily environment. It is also not very resistant to high temperatures and friction - if, for example, you want to quickly unfold a roll with stretch film, your work glove holding the roll will certainly not survive it.

Nitrile, very good abrasion resistance and additional resistance to oils and greases. Unfortunately, usually nitrile coated gloves give me a firm grip because of the grip. Here too, nitrile foam comes in handy. Nitrile foam coated gloves are currently the best solution when it comes to coating protective gloves. Very durable, resistant to some chemicals and very flexible.

Polyurethane? Popular for coating the so-called assembly gloves made of thin nylon. It has good abrasion resistance, but usually poor adhesion.

How to choose a coating suitable for your work?

As always, think about what activities you do the most and choose the material that suits your needs. If you are grabbing and carrying a lot of heavy items, you probably need the best grip and a firm grip. If you work with engines, choose oil resistant gloves.

It is also worth paying attention to gloves with an additional structure in the grip part or on the fingertips - e.g. made of silicone. This element will significantly improve the grip of the glove and prevent items from slipping out of the hand. However, always remember to check what elements and materials you touch when working with work gloves. Gloves like to leave marks on the objects they touch, which, as they oxidize, can turn into, for example, indelible smears or discoloration (such as, for example, traces of latex gloves on parts of a car body, if they are then covered with varnish, blemishes will appear at the points of contact over time. ).

Anti-cut or what?

A few years ago they were an absolute hit and a novelty, unfortunately for many users they remain new to this day. Working with sharp objects, glass, sheet metal, assembly of household appliances are industries in which employees are exposed to frequent damage to their hands with sharp objects. Can you save on it? Rather not, not only that the damage will eliminate the user's ability to work, but it may also expose the employer to legal consequences and damages. Cut-resistant gloves are made of flexible and durable cut-resistant fibers. Currently, their flexibility does not differ from standard work gloves. It is also worth adding that this type of protective gloves is extremely resistant to mechanical damage. But, what can be explained, check out our test:

Nice shock right?

Economics, costs, consumption

The icing on the cake of our entry, the question is, is it even profitable? Premium work gloves? But for PLN 15? We understand both sides of the barricade. If your company has a huge turnover of employees, it is hardly surprising that you do not want to invest in solid gloves. Remember, however, that working in well-chosen gloves with appropriate parameters is much more pleasant and efficient. In short, you can do more with less effort. It is also worth remembering that well-chosen work gloves will allow your hands to rest while you stop screwing, drilling or other work. Just after a few hours "on the job" you will not have the feeling of stones tied to your hand.

How many times have you finally cut your hand deeply cutting aluminum profiles, prying some plate or carrying heavy elements with sharp edges. Working with a cut hand becomes much less efficient and, above all, tedious.

Let's also look at the dry facts. Count how many pairs you or your entire team are currently using. One pair a day? Ok, PLN 3 a day x 5 days a week gives us PLN 15. We encourage you to buy gloves of premium brands, well-chosen and fitted and check how much your comfort will increase and how much wear will decrease. Our experience shows that the implementation of more expensive models of gloves often reduces the cost of the purchase. Magic? Not at all. In addition, your purchase costs also include the time and gas you spend on trips to the warehouse / market to buy gloves, or shipping costs if you order online.

When it comes to premium gloves, it is also worth mentioning their storage. We often lose, forget, leave our favorite gloves. How can I fix it? Glove holders are simple tools for attaching gloves to a belt or garment. If you get used to the use, your gloves will always be at hand. Here's how the clips look live:

Summary

Once upon a time, working with gloves was impossible for me. Uncomfortable, hot, no grip, slipping objects ... It was also hard to find out, so much money for gloves. Today I no longer struggle with abrasions and damage to my hands and I absolutely cannot imagine working without working gloves. All you need to do is choose the right model for the work we are currently doing to enjoy the convenience, comfort and safety. Is it worth buying for yourself? And for my team? In our opinion, it's worth it. As mentioned above, in this case more expensive is cheaper.